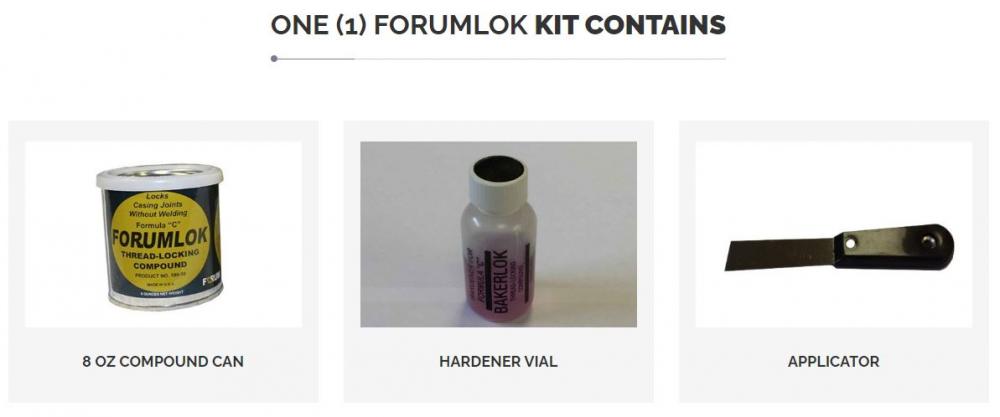

FORUMLOK THREAD LOCKING COMPOUND Product No. 199-50 Kit

Forumlok is a superior thread locking compound, commonly used for casing, tubing and drilling joints to prevent accidental detaching of string components during drilling operations.

– Withstands high breakout torque: Tests under bottom hole temperatures ranging from 50° through 400° F showed Forumlok withstood greater torque than a standard joint welded in three places with 2 inch beads.

– Easy Mixing: Forumlok thread locking compound is specially formulated to ensure a stable mixing consistency in most operational environments.

– Long “Potlife” after mixing: Special formulation (catalyst and compound) in Forumlok insures a “potlife” in excess of one hour; even at high.

– Unchanged by vibration: At 400° F Forumlok treated joint was subjected to a steady breakout torque for 8 hours, white being subjected to continuous Air Hammer vibration. Breakout torque was increased to reach six times the prescribed 3,300ft-lb makeup torque, before the joint finally broke.

– High Lubricity: Tests were conducted using Forumlok side by side with API modified thread dope. With the same amount of torque, the Forumlok treated joint was cooler, than the joint treated with standard thread dope. Forumlok has a 1.18 Friction Factor/Torque Factor.

– Leak-proof seal: Couplings made up with Forumlok thread locking compound, using standard toque, were tested with water pressures in excess of the listed bursting force of the casing, without any signs of leakage.

Details

Manufactured By:

Hallmark Sales Corporation Items